Designing for a carbon saving: North Quay House

5 March 2021

The North Quay House project is an office extension and redevelopment of an existing building overlooking the Floating Harbour in Bristol city centre.

The project purpose is to renew this building and increase the floor area to extend its lifespan. Reusing the existing building represents a significant carbon saving relative to demolition and new build. For the extension, efficient design of new materials aims to produce a low carbon design and minimise environmental impact.

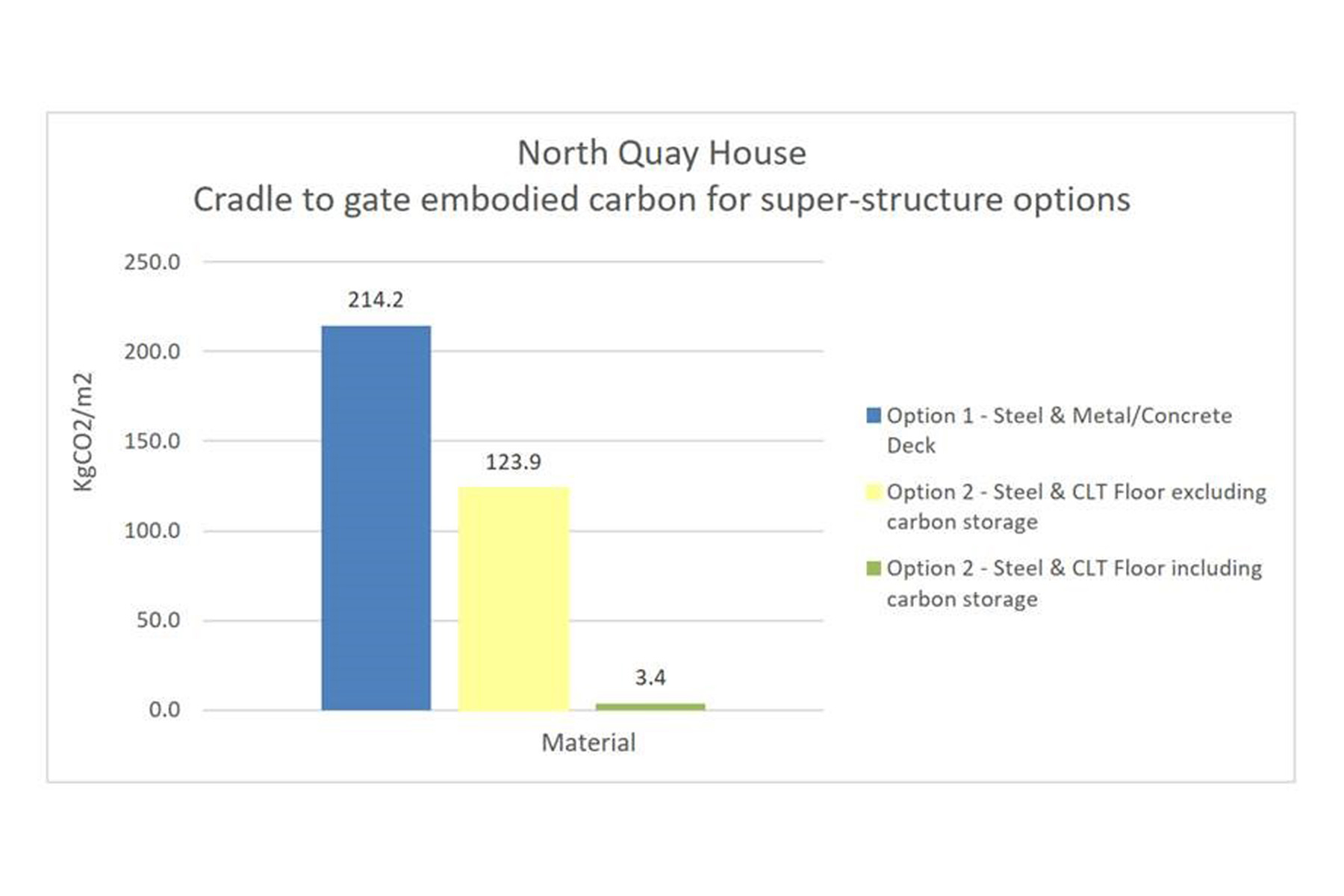

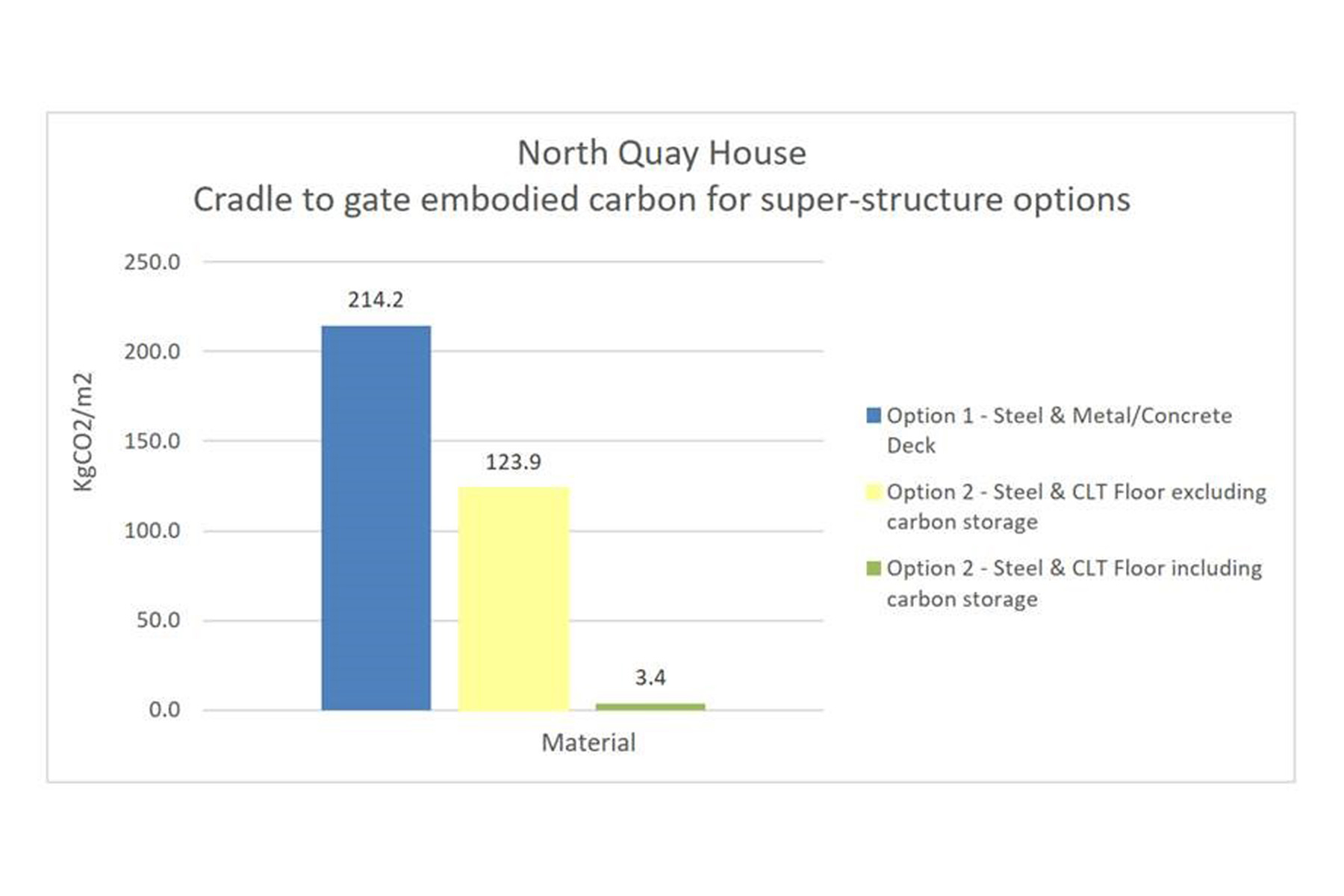

At the concept design stage we analysed both a steel frame with metal deck concrete floor (similar to the existing) and steel frame with a Cross Laminated Timber (CLT) floor. Early cradle to gate embodied carbon estimates were carried out for both options, shown in the chart above. The CLT option (123.9 kgCO2/m2) showed a significant embodied carbon saving at 42% (90.3 kgCO2/m2) lower than the concrete floor option (214.2 kgCO2/m2). For comparison, the estimated typical energy consumption of an office building in use would be around 100kgCO2e/m2 each year (according to the Institution of Structural Engineers). This carbon calculation was solely for the superstructure although additional savings are possible in the substructure due to the reduced weight of the CLT floor compared to concrete. Presenting the potential carbon saving to the client in a quantifiable manner enabled them to make an informed decision to opt for the lower carbon timber scheme.

In some cases a timber structure must be encapsulated for fire protection. Using the latest guidance by the Structural Timber Association we were able to justify the building as low risk and suitable for timber’s natural charring protection in a fire. Through early consultation with building control we were able to confirm that exposed timber soffits are acceptable here. Again this reduces the need for new construction materials, minimising the embodied carbon. This feature we will continue to monitor as the project progresses.

Maria Schaerer

Senior Engineer