How to save a 30 tonne tank from collapse

01 June 2023

Using a complex sequencing of new supports to suspend the tank

The challenge

We were tasked with rescuing a 30 tonne, cast iron water tank located in a difficult spot within the Grade II* listed Tone Works site in Somerset. The tank, supported 2m off the ground by beams, columns and props has suffered decades of exposure to harsh conditions causing the supports to decay. The risk of collapse was very real. If the tank fell to the ground, it would take the adjacent buildings with it.

The constraints

Building new supports under the tank was an obvious answer to the problem, but not possible. It was not safe to go under the tank and hidden voids in the ground would make founding new vertical structure very difficult.

What about demolishing it? Is that cheaper and safer than trying to save it? Does that align with conservation principles? Discussions with the design team returned a resounding “no”. So, the tank was to be rescued without going underneath it or entering it. Our solution also had to account for the restricted site access and the tank’s condition. As a bolted cast-iron structure of unknown age, care was needed when applying new forces to it.

We quickly concluded the tank had to be hung from above. It made sense to utilise the brick masonry walls either side to support a new structure spanning over the tank.

Tension hangers needed to be connected to the tank but half a metre of tar-like sludge and vegetation prevented access to the base. Therefore, a two-stage plan was formed: Hang the tank from its walls and the base would hang in tension. This allows access underneath for cleaning as the tank’s full self-weight is supported, and the original beams and columns are still in place. With the base exposed, more tension hangers could be installed, allowing inspection, removal and/or replacement of the original structure underneath.

The design

This is where our close relationship with Corbel Conservation Ltd, the main contractor, showed its value. Corbel were already on site and on hand to provide invaluable support to our design work.

Seven primary steel beams span over the tank, supported off new padstones in the existing walls. Secondary beams span perpendicular to these and are aligned with the tank walls below. 62 threaded rods hang from the beams to suspend the tank.

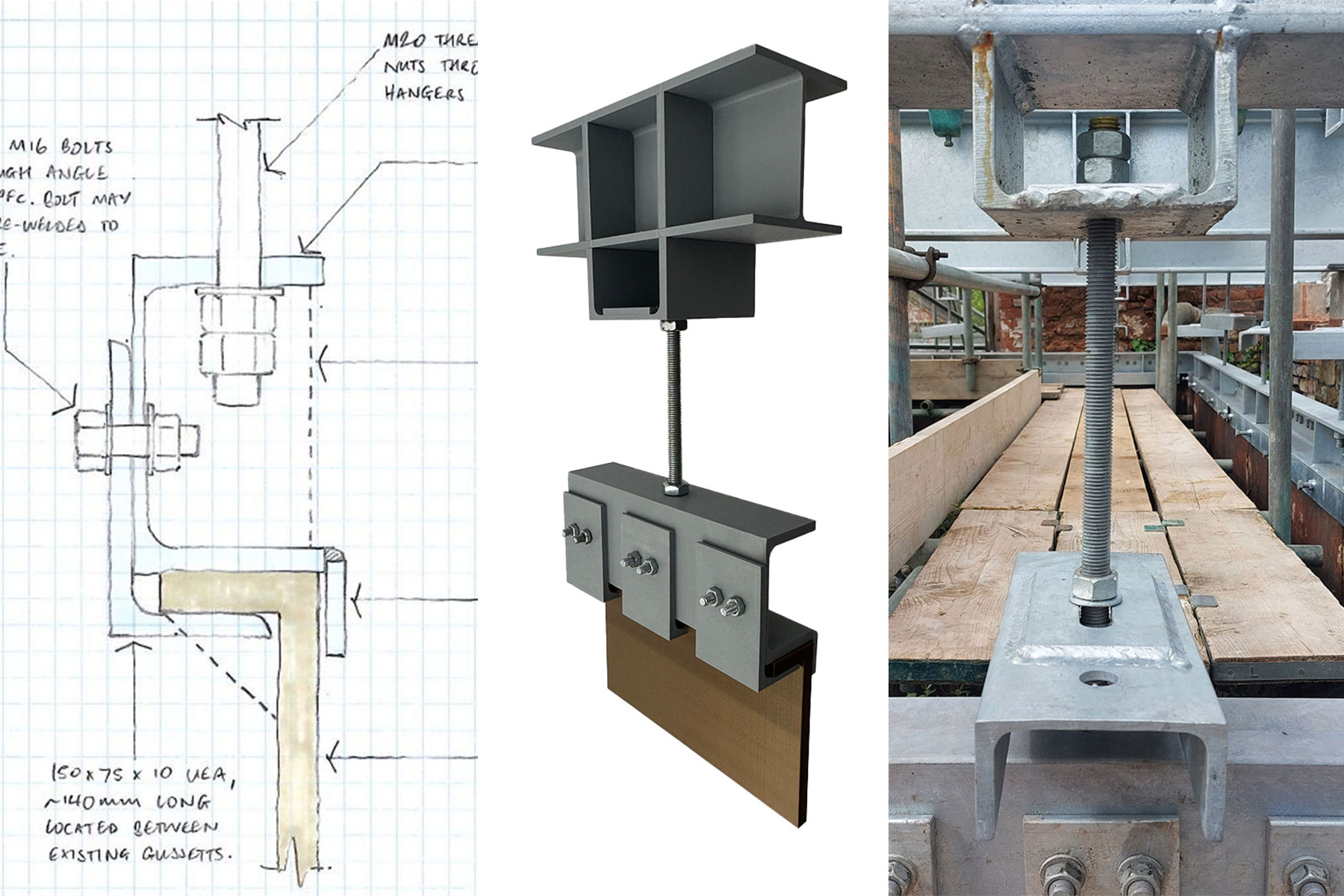

The connection between the hangers and tank was critical. Following an exchange of ideas with Corbel, we designed a clamp utilising a flange at the top of the tank walls. This could be installed safely and speedily from above and minimised damage to the historical material by avoiding any drilling .

Next came the methodology for taking up the load of the tank in the new hanging structure. Unusually for us, we were fully involved in developing the method alongside Corbel as the lifting process was inextricably linked to the hanger design. Crucially, we had to find a way of ensuring the load was taken up by the hangers and beams correctly. An overloaded hanger could lead to failure of the entire system.

With costs a key consideration, our solution used hand-operated hydraulic jacks combined with load cells. Strain gauges on every hanger would have provided accurate, real-time data on the loads in the rods, but were prohibitively expensive. Our method only required two jacks and two load cells. These kits were moved between hangers in sequence and Corbel used our loading plan to tension the hangers to 50%, 75%, 90% and 100% load. This incremental loading ensured the whole system was loaded evenly. At each tensioning stage, the nuts at the top of the hanger rods were simply tightened off.

With the walls of the tank now fully supported, the cleaning process is underway. In the next couple of weeks, 24 additional hangers will be installed down to the base of the tank. They will be secured with a PFC stub ‘anchor’ on the underside to spread the load on the cast iron plate.

The result

This project has secured a historically significant tank, in turn saving the surrounding buildings from potential destruction. The new supports allow safe access under the tank, not only for the purposes of assessing and repairing the original structure, but for future access by site users and visitors.

Despite being very technically challenging and under budget and programme pressures, the collaborative approach by the team meant that these challenges never seemed insurmountable.

It has been a great challenge to learn a little about hydraulic jacking and designing details which combined the temporary and permanent cases. Even more rewarding was seeing the designs go from sketch to site in a matter of weeks, with no formal construction drawings issued at all. This was only possible because of the close collaboration between Integral, Corbel and the rest of the design team.